Coating Implants with Bioactive Glass to Promote Implant Fixation

Shutterstock | edwardolive

When implanted in the body, bioactive glass triggers specific biological activity which forms a layer on the glass surface with a material similar to hydroxyapatite. This layer enables the bioactive glass to form a firm bonding with both soft and hard tissues.

Due to this behavior, bioactive glass has become the subject of intensive research to explore its potential use in the repair of damaged bone. Also, thanks to their biocompatibility, these bioactive glasses do not induce immune responses that can cause rejection of foreign materials introduced into the body.

Bioactive glass is brittle in nature, but offers a strong, lightweight and biodegradable framework to facilitate healing. Moreover, study results have shown that new borosilicate and borate bioactive glasses can enhance bone regeneration. It is also possible to adjust the composition of bioactive glass to find out the number of hours it can persist in the body before it degrades to provide the necessary support as long as is needed.1

Bioactive glass has already been shown to be effective in the repair of soft tissue, bone, and cartilage repair1. Bioactive glass has also been shown to be beneficial in periodontal reconstruction2. It also promotes healing of ulcers in patients at risk of leg amputation.3

The efficacy of bioactive glass in promoting the healing of both soft and hard tissues has led to research into its use in reconstructive surgery where the use of permanent implants is required. This article discusses how the bioactive glass material can help promote the integration of implants.

Ensuring that implants are biocompatible

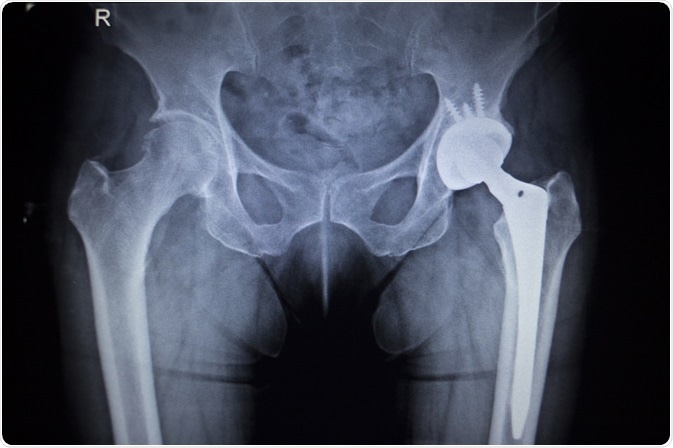

The human body has the ability to heal itself, but in the case of complex or multiple fractures or life-threatening disease or infection, the lack of the original bone hinders the healing process. In these scenarios, a bone scaffold or graft is needed to support bone regeneration and fusion. Also, it may be necessary to use implanted devices, such as joint replacements, plates or screws to replace or reinforce damaged or weak bones and joints. Similarly, implants may be needed in dentistry to help artificial replacement of a tooth root. These implants are typically in the form of a metallic screw placed in the jaw bone to provide support to one or more false teeth.

An autograft – a bone taken from another part of the body – is the preferred implant for repairing the bone since it will not be at risk of injection. However, availability or suitability of the bone to be taken can hamper this bone graft. This also leads to additional morbidity for the patient at the site from where the graft is harvested.

Although titanium alloy implants have very good biologic compatibility, the implant needs to be integrated into the bone (osseointegration) for a strong structural support and it may require several months for bone growth in and/or around the implant. Also, the implant must be morphologically and mechanically compatible to maintain good contact with the recipient bone to support the growth of bone cells. Furthermore, metal implants are at risk of getting corroded by bodily fluids and discharging potentially toxic products.

As a result, there has been a lot of research into coatings for prosthetic metallic implants.4

Coating implants in bioactive glass

One such coating material is bioactive glass which is currently the subject of intensive research. When bioactive glass is present within the body, an amorphous calcium phosphate layer is formed on the glass surface. Within hours, blood proteins and collagen are incorporated into this layer, which is then crystallized into hydroxycarbonate apatite. The resultant layer is very similar to natural bone mineral, and therefore, attaches to the recipient tissues/bone readily. Hence, bioactive glass holds potential to be used as a coating material for the integration of implants into the bone.

The incorporation of bioactive glass into polymeric scaffolding materials can help encourage the formation of a strong bond between the tissue and scaffold and improve healing rates.5 It followed that similar kinds of technologies may assist the osseointegration of the implants.

After addressing numerous technical challenges, bioactive glass has been successfully applied as a coating material for titanium implants and the resultant bioactive glass-coated implants have shown promising results in their evaluations.6,7,8 Bioactive glass coatings on dental and orthopaedic implants did not induce any inflammatory response and adverse effects in the surrounding tissue.6 In addition, bioactive glass coatings expedited cell attachment, proliferation, spreading, differentiation, and mineralization of the extracellular matrix and supported rapid bone growth.6,7 Bioactive glass-coated implants had significantly higher proportion of bone-to-implant contact.8

Bioactive glass is available in different sizes and compositions9 to meet the requirements of different applications. Indeed, it is possible to tailor bioactive glass to specifications that precisely satisfy a specific requirement, in terms of degradation rate, strength etc.

Conclusion

Implants are widely used in orthopaedic surgery to facilitate the repair of damaged or missing bone as well as in dental reconstructions. Although implants have been employed with a high success rate, rejection issues and toxicity concerns may put limitations on the procedures available. Also, it may require several months for integration of an implant into the recipient bone and therefore, the risk of failure and recovery times will be high.

Bioactive glass is biocompatible, has good strength and promotes tissue regeneration. These qualities make it a useful material in tissue engineering. The recent technological developments have enabled the coating of metal implants with bioactive glass. Bioactive glass-coated implants have been shown to be advantageous in terms of patient safety and recovery.

Thanks to the bioactive glass coating, the metal implants are protected from being corroded by bodily fluids, thus reducing the risk of potentially toxic substances entering the body. The bioactive glass coating also encourages new bone growth, thereby securing the implant in the bone more rapidly.

Bioactive glass coatings can be applied on implants to support implant fixation, maximize implant effectiveness, and enhance healing rates. Mo-Sci provides superior quality bioactive glass in a form ideally suited for coating implants and in tailored compositions to fulfill specific requirements.

References

- Rahaman MN, et al. Bioactive glass in tissue engineering. Acta Biomaterialia 2011;7:2355 2373.

- Sohrabi K, et al. An evaluation of bioactive glass in the treatment of periodontal defects: a meta-analysis of randomized controlled clinical trials. J Periodontol 2012; 83: 453 464.

- The American Ceramic Society Press release 4 May 2011. Available at https://www.sciencedaily.com/releases/2011/05/110503133056.htm

- Lopez-Esteban S, et al. Bioactive glass coatings for orthopedic metallic implants. Journal of the European Ceramic Society 2003;23:2921–2930.

- Lu HH, et al. Three-dimensional, bioactive, biodegradable, polymer-bioactive glass composite scaffolds with improved mechanical properties support collagen synthesis and mineralization of human osteoblast-like cells in vitro. J Biomed Mater Res 2003;64A:465–474.

- Mehdikhani-Nahrkhalaji M, et al. Biodegradable nanocomposite coatings accelerate bone healing: In vivo evaluation. Dent Res J (Isfahan). 2015;12(1):89 99.

- Chen Q, et al.Cellulose Nanocrystals--Bioactive Glass Hybrid Coating as Bone Substitutes by Electrophoretic Co-deposition: In Situ Control of Mineralization of Bioactive Glass and Enhancement of Osteoblastic Performance. ACS Appl Mater Interfaces. 2015 Nov 11;7(44):24715 25.

- van Oirschot BA, et al. Comparison of different surface modifications for titanium implants installed into the goat iliac crest. Clin Oral Implants Res. 2016;27(2):e57 67.

- Mo Sci Corporation website. http://www.mo-sci.com/en/products

This information has been sourced, reviewed and adapted from materials provided by Mo-Sci Corp.

For more information on this source, please visit Mo-Sci Corp.

Last updated: Dec 19, 2017 at 8:23 AM

.png)

No hay comentarios:

Publicar un comentario