Bioprinting in Medicine

Bioprinting is a method used in tissue engineering that allows the creation of complex biological structures.

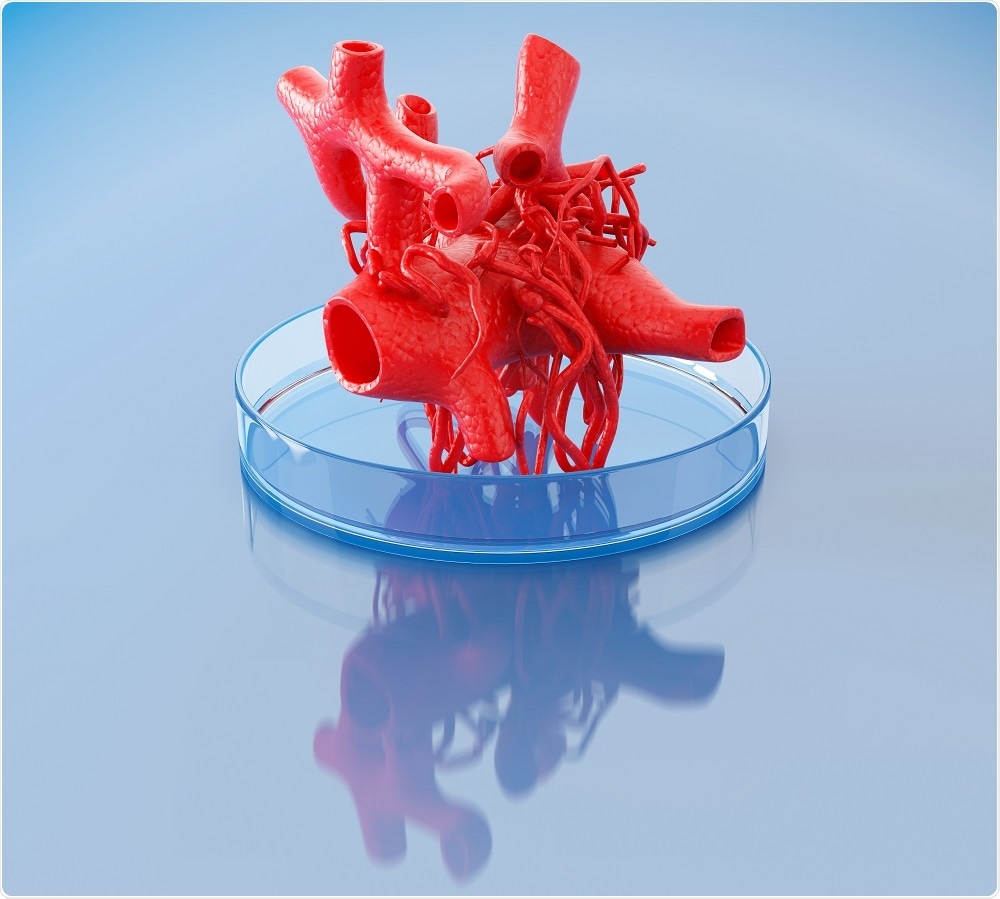

Image Credit: Iaremenko Sergii / Shutterstock

Image Credit: Iaremenko Sergii / ShutterstockIn standard tissue engineering, cells are seeded onto solid, biodegradable scaffolds, and are then induced to grow. However, that conventional approach is limited in its ability to replicate the smaller structures of a tissue.

With bioprinting, cells are combined with the matrix and deposited precisely to form the desired tissues and organs. Common techniques include jet printing and extrusion methods. Bioprinting has broad applications in biology and medicine.

Although modeled on conventional 3D printing, bioprinting is vastly more complex. Recreating tissues and organs also requires the recreation of structures and functions within the tissue, including signaling networks, cellular interactions, multiple cell types, and physiological activity.

Conventional tissue engineering approaches typically use a fabricated 3D scaffold to build up the three-dimensional cell structure. However, those approaches are not able to reproduce complex inner structures of the tissues. One advantage of bioprinting id that its additive approach allows reproduction of fine 3D structures within the tissue, with precise control of the positioning of cells.

Bioprinting is a very new science with a wide array of potential applications. Some examples of applications that have been investigated or are in development are given below.

Medical imaging

Bioprinting can be combined with CAD technology to make 3D models based on patient medical images. Images are typically collected from CT and MRI scanning, but other imaging modalities like ultrasound or angiography have also been used.

Heart repair

Prosthetic replacement heart valves are associated with high rates of complications, such as mechanical failure and calcification. One approach to heart valve replacement uses extrusion-based bioprinting to build a heart valve conduit composed of hydrogel and human aortic valve interstitial cells.

The results showed that the valve was viable, and subsequent studies proved that a complex living aortic valve conduit could be constructed with bioprinting. In another study, laser-assisted bioprinting was used to make a patch for regeneration of cardiac tissue out of human umbilical vein endothelial cells and mesenchymal stem cells.

Printing muscle and bone

Bioprinting technology can be used to regenerate bone and cartilage. Cells are delivered via extrusion-based bioprinting. Cells printed in this way were shown to maintain viability and showed osteogenic differentiation.

Repair of nerve injury

Researchers have fabricated scaffold-free nerve grafts for regeneration of peripheral nerve injury. The resulting graft was implanted into a rat and axons at the proximal stump grew to reach the distal segment of the sciatic nerve in the print.

Skin tissue

Jetting-based bioprinting has been used to create biomimetic multilayered skin tissue composed of human skin fibroblasts and keratinocytes. In this application, cells and collagen hydrogel were printed separately. The resulting tissue showed formation of layers, resembling dermal and epidermal skin layers. And an in situ skin printer has been developed to print skin cells directly onto the body for burn wounds.

Commercial bioprinting

Organovo, of San Diego, California, was the first company to commercialize 3D bioprinting. Its bioprinter product can print a variety of tissues for surgical reconstruction or transplantation. Its human liver tissue has been used to screen drug compounds for treatment of non-alcoholic steatohepatitis and its human intestinal model can be used to study toxicity and inflammation.

Reviewed by Hannah Simmons, BS

Sources:

- Bioprinting technology and its applications.

- Three-dimensional printed trileaflet valve conduits using biological hydrogels and human valve interstitial cells.

- Three-dimensional fiber deposition of cell-laden, viable, patterned constructs for bone tissue printing.

- Toward engineering functional organ modules by additive manufacturing.

- Multi-layered culture of human skin fibroblasts and keratinocytes through three-dimensional freeform fabrication.

Further Reading

Last Updated: Jun 7, 2018

No hay comentarios:

Publicar un comentario