Investigating the Unique Nanomechanical Properties of Tooth Enamel

Thought LeadersDr Yeau-Ren Jeng

Thought LeadersDr Yeau-Ren JengEndowed Chair ProfessorNational Chung Cheng University

An interview with Dr Yeau-Ren Jeng, conducted by Jake Wilkinson, MSc

What biomaterials research are you currently working on?

My background is in tribology, which is the science of the interactions between surfaces in relative motion. This involves looking at behaviour, such as friction, wear and lubrication, and the relationships between them.

My research is focused on biomaterials because this is what fascinates me most. Biomaterials are able to adapt to working in all kinds of different environments. Unlike manmade engineering materials, which are designed, biomaterials have been created through evolution, which represents thousands of years of trial and error by nature. Biomaterials tend to be superior to synthetic materials and the lessons we learn from them could help us towards better engineering materials.

What types of biomaterial are you interested in?

I’ve spent the last few years working on tooth enamel. I am fascinated with enamel in particular because it has an ideal combination of hardness and toughness. Most hard materials tend to be brittle whereas tooth enamel is still relatively elastic, which makes it useful in applications involving high levels of use and friction.

Tooth enamel consists of minerals and salt proteins, and looking at its composition alone you would expect it to be brittle, however the way it is structured means this is not the case. I want to learn how Mother Nature can make non-brittle tooth enamel from such a brittle material. If we can discover how tooth enamel is structured and composed, we can use this knowledge to develop better, long-lasting engineering materials with a very high wear resistance.

How have you been using nanoindentation as part of your enamel research?

We have been carrying out several rigorous tests on enamel. I and my partner, a dentist who has previous experience with enamel testing, have been using depth-sensing techniques and nanomechanical testing to investigate enamel’s structure.

In clinical dental practices, topical fluoride treatments are frequently given to repair tooth enamel and to prevent dental cavities from forming. Whilst the majority of dental practitioners believe that fluoride deposits are hard and do not require reapplying, my partner found that the initial doses of fluoride that he was giving his patients needed topping up.

Previous research into fluoride deposits on enamel, which used macroscopic testing methods, had shown that fluoride deposits were hard. However, using the nanoindentor, which allowed us to position over a single fluoride deposit and test it in isolation, we found that the deposit is actually soft, and wears very easily.

What different techniques do you use alongside nanoindentation?

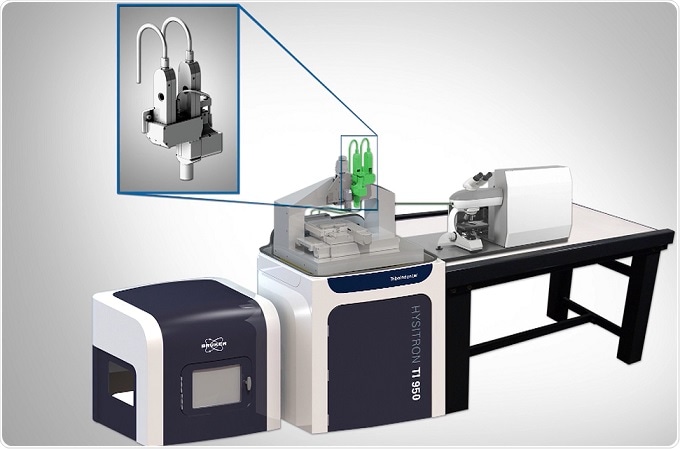

At the beginning of my research using depth sensing and indentation I performed my experiments using a TriboScope integrated with an AFM.

We now use the PI950, which allows us to use AFM to scan the sample’s surface and determine points of interest, which we then test using the indentor. Integrating SEM and TEM with the nanoidentor lets us observe the evolution of microstructures within the enamel and determine the relationship between different material components.

This has led to developments that would have not been previously possible to observe, such as the discovery of small volumes of hard coating within enamel, or the adhesion of materials, such as carbon, to provide a combination of low friction, high wear properties.

How closely do you work with Hysitron?

We work closely with Hysitron and we both support each other. We have ideas that we discuss with them in how their system can be improved, and they also let us know whenever different developments are made that can help us.

What other updates have you made to your Hysitron system?

One exciting recent development is the integration of our Raman system into the depth-sensing indentation system we are using. This allows us to analyse the areas affected by stress, strain, or temperature. These types of changes can be observed, via Raman, as changes in hybridisation states (sp2 or sp3) and other changes in bonding structure.

This analysis allows us to observe how the thermal effects of load and of any energy input into the material in surgery change its mechanical properties and tribological behaviour. This previously unknown information can lead to better coatings for fabrication tools, and could even be used in the electronics industry for the magnetic decoding used in hard discs and data storage systems.

When do you expect man-made composites that truly mimic biological composites to become available?

This all depends to what degree we can emulate biomaterials. Though we have a long journey ahead of us, we are well on our way to learning more and developing better engineering materials.

Synthetic biomaterials will make our lives better and greener. They could also be designed to be responsive, to become a smart material, which will last longer and remain functional in many different environments. Materials such as these will improve our lives for a long time to come.

About Dr Yeau-Ren Jeng

Yeau-Ren Jeng is Endowed Chair Professor of National Chung Cheng University, a Founding Director of Advanced Institute for Manufacturing with High-tech Innovations (AIM-HI) and a professor of mechanical engineering.

His research has provided significant benefits to multiple industries, including the automotive, material, electronic, manufacturing, and nano-related industries. His publications are widely cited, including several textbooks and handbooks.

He is the advisor of several dissertation awards from Ministry of Science and Technology and the Chinese Society of Mechanical Engineers.

He holds over 20 patents and has received numerous awards, including the McCuen Special Achievement Award from General Motors, the Innovative Research Award from American Society of Mechanical Engineers, the Society of Tribologists & Lubrication Engineers Walter Hodson Best Paper Award, the Captain Alfred E. Hunt Memorial Medal, the Research Invention Award from the President of Taiwan, and the Outstanding Research Award from Taiwan’s Ministry of Science and Technology. He is also the recipient of the Mechanical Engineering Medal from the Chinese Society of Mechanical Engineers. He is on the editor board of several internationally renowned journals.

Professor Jeng received the highest academic honour from the Ministry of Education of Taiwan in 2017.He is on the advisor board of university administration for National Taiwan University, National Cheng Kung University, National Taipei University of Technology, and National Formosa University. He is also on the review committee of M-ERA of European Union Horizon 2020, Russian Science Foundation (RSF), and German-Israeli Foundation for Scientific Research and Development (GIF).

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.

No hay comentarios:

Publicar un comentario