Purifying Proteins from Mammalian Cell Culture

insights from industryDennis Karthaus, MScTeam Leader Cell CultivationIBA Lifesciences GmbHAn interview with Dennis Karthaus and Sarah Ludwig conducted by James Ives

insights from industryDennis Karthaus, MScTeam Leader Cell CultivationIBA Lifesciences GmbHAn interview with Dennis Karthaus and Sarah Ludwig conducted by James IvesRecombinant proteins can be produced using many types of cells including, yeast, bacteria, insect and mammalian cells. What advantages are there to producing recombinant proteins using mammalian cells over others?

In many cases mammalian cells are the only option to produce recombinant proteins with correct post-translational modifications, e.g. glycosylation, which are required for proper function of the therapeutic protein.

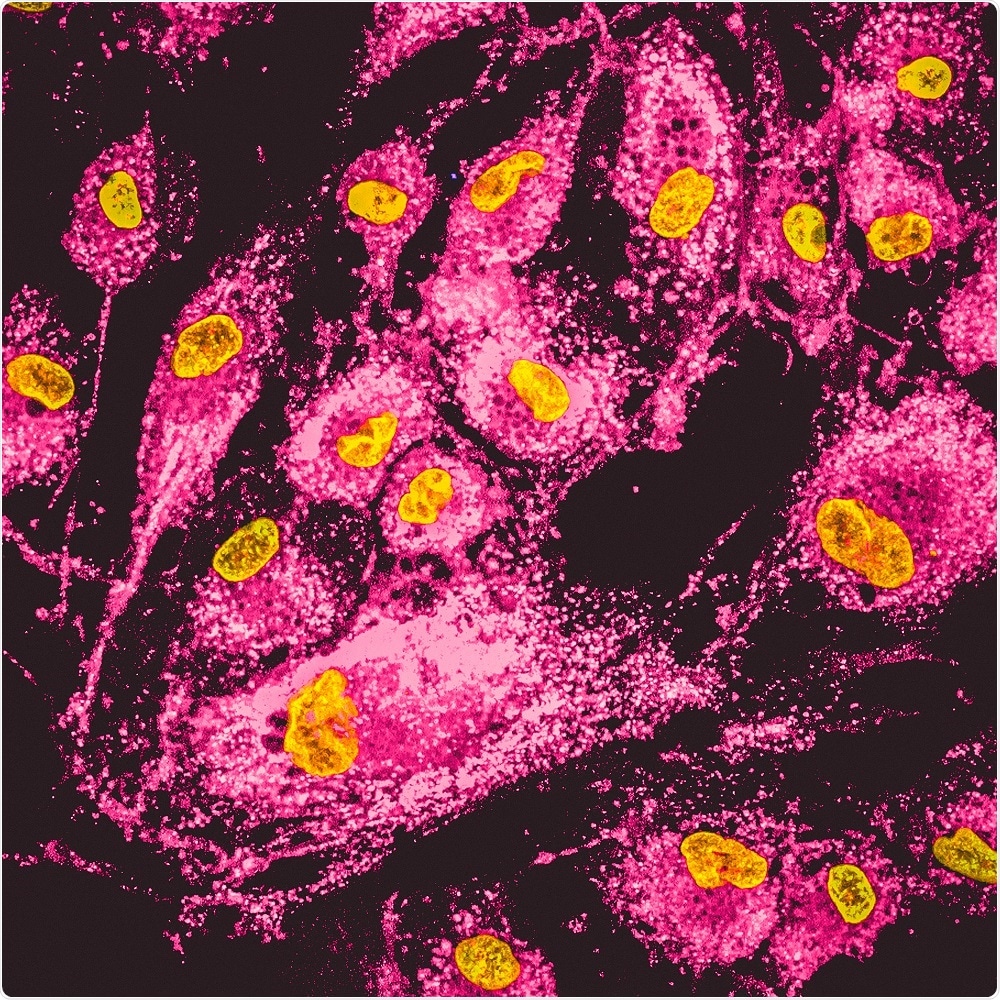

Vshivkova | Shutterstock

E. coli lack the ability to fold complex mammalian proteins and to perform correct post-translational modifications. In addition, the post-translational modifications of yeast and insect cells differ from mammalian cells. Therefore, these host organisms are often a suboptimal option for the production of mammalian proteins, especially if the glycosylation is complex or sialyation is required.

Furthermore, the ability of mammalian cells to secrete proteins into the medium simplifies the downstream process. In contrast to bacteria, mammalian cells can produce large proteins of more than 50 kDa efficiently. Bacterial systems often form inclusion bodies if larger proteins are expressed. In addition, no endotoxins are introduced into the protein sample by the expression procedure.

What are the main applications of recombinant proteins produced in mammalian cells?

Many recombinant proteins produced in mammalian cells are applied for cancer therapy. Especially antibodies and antibody like molecules, which are the most frequently produced proteins.

Membrane proteins are also very important because they are commonly used to study the effects of potential drugs and their mode of operation.

What are the challenges in producing highly pure recombinant proteins for R&D purposes

I think the major challenge is the simultaneous purification of different proteins in a short time with a standard method. Additionally, this method should need no optimization of the purification strategy for different proteins and provide high purities of more than 90%. The purification system must be cost efficient, compatible with many host expression systems and should provide a high flexibility regarding the buffer composition.

Most companies or institutes which must express many different proteins, e.g. during the screening phase of new drug candidates, are facing the same challenges every day. It is worth mentioning that a lot of these proteins are expressed at low levels, especially membrane proteins, making their purification very challenging.

Since different amounts of protein are required for different applications, the purification methods must be easily scalable and should provide a sufficient protein purification capacity.

What is the current standard method to clarify and purify these proteins in your lab? What are the advantages and limitations of this method?

Prior to the Sartoclear Dynamics® Lab method, we used centrifugation for the clarification. First, we pelleted the cells for 10 minutes at 300 g. Then we added a second centrifugation step at 3,000 to 10,000 g to remove cell debris and to prepare the sample for the Strep-Tactin®XT high capacity affinity chromatography purification.

The major drawback of this method is the time needed for the two centrifugation steps. Balancing the tubes, removal of the supernatant, the time for cleaning the centrifugation tubes and the centrifugation time itself can take up to 44 minutes.

Another bottleneck of the current method is the fact that the centrifuge must be available for clarification and since other groups in the lab are using the same machine, this is not always the case.

Finally, the centrifugation process is not very flexible with respect to the sample volume. Our centrifugation tubes must be filled up to at least 80% of the tube volume for higher centrifugation speeds. Therefore, samples below 800 ml must be distributed to several smaller tubes which requires more hands-on time.

Recently you have evaluated a new method of cell clarification and filtration from Sartorius, how does this differ from previous techniques?

The Sartoclear Dynamics® Lab filtration technique improved our clarification process remarkably. In total we were able to reduce the time needed for clarification from 44 minutes down to 12. In addition, because all Sartoclear Dynamics® Lab products are sterile single use, the risk of cross contamination was eliminated, and the filtrate was sterile.

Another aspect is the simplification of the whole process. Since we do not have to rely on a large centrifuge anymore we can conduct the clarification right away in our cell culture lab.

Finally, up and downscaling of the method is quite easy as it is only necessary to adjust the amount of filtration aid.

How were the product quality, protein yield and the IgG aggregation rate affected by using the Sartoclear clarification and filtration method when compared to centrifugation? How was this tested?

Of course, every time you change a method you must ensure that the quality of your product remains unaffected. For us as an ISO 9001 certified company this is absolutely mandatory. To test the influence of the Sartoclear Dynamics®Lab clarification process on the product quality, we clarified a MEXi-293E (HEK293) culture expressing a monoclonal antibody fused to a Twin-Strep-tag®, using our standard centrifugation process in parallel to the Sartoclear Dynamics® Lab method.

After clarification we purified the antibody from the different clarified samples via Strep-Tactin®XT high capacity gravity flow purification. The eluate was analyzed by SDS-PAGE, western blot, photometric measurement at 280 nm and size exclusion chromatography.

The SDS-PAGE and western blot analysis revealed that there was no difference in protein purity between the two clarification methods and that 100% purity was achieved with Strep-Tactin®XT high capacity purification.

The use of Sartoclear Dynamics® Lab did not influence the aggregation of the antibody, because the ratio of aggregated antibody, determined by size exclusion chromatography, was the same as for the centrifuged sample.

Finally, we found that the protein yield was the same for both methods which proved that no antibody was bound to the components of the Sartoclear Dynamics® Lab system.

In summary, the use of the Sartoclear Dynamics® Lab method had no negative effect on protein’s quality or quantity.

In your research, antibodies were labelled with the Twin-Strep-tag® for the purification step. Why do you use this affinity tag system for your purification?

The Strep-tag system allows the purification of proteins under physiological and denaturing conditions with purities usually exceeding 90%. Compared to all other affinity systems the Twin-Strep-tag® in combination with Strep-Tactin®XT reaches the highest binding affinity in pM ranges, while the system still maintains its reversibility. This is advantageous specifically for low concentrated samples in large volumes.

Due to the small size of the Strep-tag®II (8aa) and the Twin-Strep-tag® (28aa) there is no need to remove the tag.

In addition, the system is compatible with a large variety of reagents like detergents, high salt concentrations, reducing agents, chelators, etc.

These properties combined with the fact that the system is suitable for protein purification from bacterial, yeast, insect and mammalian hosts make this system the superior tag system.

It is easy to use without the need for optimization like for example adjusting the imidazole concentration for elution when using His-tag system. This makes the Strep-tag system the perfect solution for the protein purification challenges I have mentioned earlier.

In your research, samples that were centrifuged were not sterile which could be important for many applications and would require a separate sterile filtration step. How would this have been achieved and how would this have affected the procedure used?

We filtered the sample with a 0.2 µm bottle top filter if sterility is required. Of course, this leads to additional process time for clarification and additional costs.

The advantage of the Sartoclear Dynamics® Lab system is that this filtration step is already included in the clarification process.

Therefore, if sterility is required, we do not have to add this step separately. This increases the time we save by using the Sartoclear Dynamics® Lab system compared to our standard method.

What limitations are there for the Sartoclear method of mammalian cell clarification and filtration?

In our hands, we do not see a limitation on this method. Users should check for the full recovery of their recombinant protein after clarification before using this method regularly, to be on the safe side.

Recombinant proteins have lot of potential in a wide range of applications. What advancements do you hope to see to increase their scalability and widespread use with respect to your R&D applications?

The production of recombinant proteins is still a production in a black box system. Indeed, we have learned a lot about how cells express proteins and which factors can influence protein quantity and quality.

Nevertheless, many aspects of how cells process proteins are still unclear. I think that the improvements in structure analysis, the use of CRISPR/Cas and the great advancements in the field of data analysis and data mining combined with high throughput automatization will lead to more comprehensive knowledge of these intracellular processes. This in return will lead to streamlined protein production processes.

The trend of decreasing the expression scale and increasing the throughput of proteins in an early research and development phase will drive the need for purification systems and formats that support this high throughput processes.

Where can readers find more information?

More information can be found at IBA Life Sciences, Sartorius.

About Dennis Karthaus, MSc

Dennis Karthaus received his master`s degree in biotechnology from the University of Applied Sciences in Bremerhaven. During his thesis at the department of Pharmaceutical Biotechnology at the Fraunhofer Institute for Toxicology and Experimental Medicine he worked on the development of protein purification platforms and in cell line development.

In 2012, Dennis Karthaus joined IBA Lifesciences. He is responsible for the mammalian custom protein expression & purification service and the product development in this field.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.

No hay comentarios:

Publicar un comentario